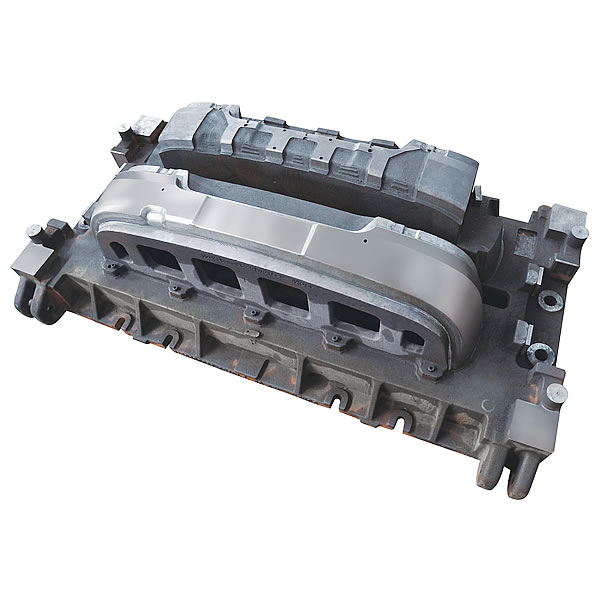

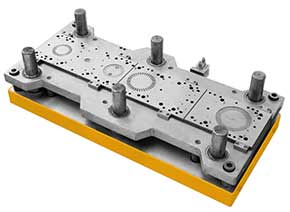

Stamping Die

Customized precision punching mold metal stamping mold

Parts description:

Product Name: High quality customized precision punching mold metal

stamping mold progressive concrete stamping die

Product Material: Carbon steel

Material: Steel

Mould life: 250000-300000shots

MOQ: 1 Set

Specification: Various sizes,customized

Cavity: Multi Cavity

CONTACT US NOW WATCH VIDEOBASIC INFORMATION

|

rand Name |

OEM |

|

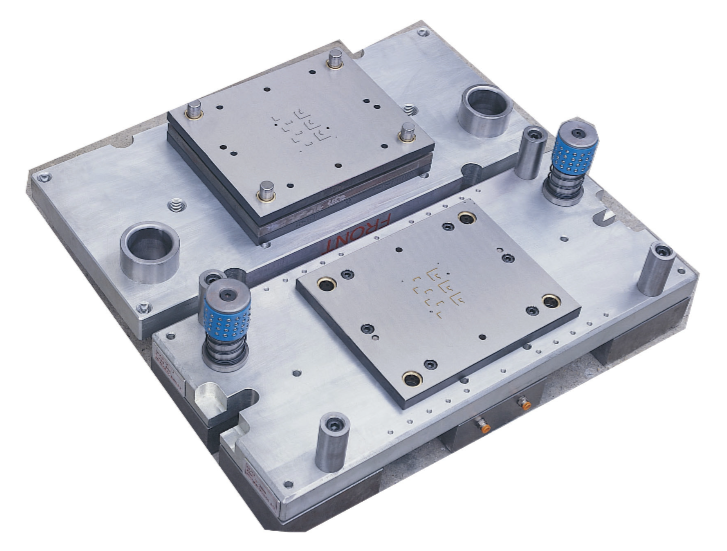

Die Tipe |

progressive punch die |

|

Draw Format |

Auto CAD/DWG/PDF ect |

|

Tolerance |

±0.002mm |

|

Hardness |

Upon request |

|

Mould size |

Customized size |

|

Production Application |

Mobile/ laptop/ digital cameral/ HD digital TV/ automobile/ electron ect |

|

Certificate |

ISO 9001:2008 & ISO 14001:2004 |

|

Surface Tratement |

Polishing/ mirror polishing/ plating/ heat treatment or according to your parts |

|

Precision Machining |

CNC/ surface granding machine/ punching machine/ sandik wire cutting/ EDM/ WIDA optical curve grinder ect |

|

Measuring Instruments |

Profile projector/ electronic height gauge/ 2D measuring instrument/ vernier caliper/ microscope/ micrometer ect |

|

Steel Material |

KD20/ DC53/ GD650/ SKD11/ SLD/ YG15/ CR12MOV/ SKH-9/ Tungsten ect |

|

Mould Life |

Depends on the steel material and your request |

|

Main Service |

Made-to-order |

TECH AND BUSINESS SUPPORT

Tech support

- ODM support, tmetal engineers could provide ODM suggestions from cost and manufacturing tech side

- 3D scanning and 3D model building

- 100% CNC custom manufacturing for logo, pattern and other special features

- One stop solution for all mechanical parts from rapid prototype , mold making, to finish parts assembly

Business support

- Sign NDA with all customers if request

- Accept Low volume business

- Could turn back the mold charge for High volume projects; for startup companys or old customers lack

of money, part of tooling charge could be spared to the production piece price

- Competive payment terms for long term copperation customer.

- Logistic support, Tmetal have very competitive logistic chain system, will optimize customer logistic chanel

and offer the best and cost -effective logistic option to all customers

- Customer china local project management and QC managment assitance